The Chubb Archive is part of The History of Locks Museum Resources

Contact our curator for more information

© 2004 - 2016

Your one-stop resource for dating & information on vintage and antique Chubb Locks, Safes & Security Equipment

Export is Fun

Mr. D.R.E. Ibbs’ personal memories of his 41 years with Chubb

Back to the Midlands - Part 1

I decided my headquarters would be in Birmingham, the branch office where I would have been manager some years earlier, but for Johnston's intervention. Not the same branch at which I had been trained in the 1950s but a group building in Lionel Street which we shared with Chubb Alarms. Originally, several group companies had been located there under a policy of amalgamation but gradually, many had moved out, leaving the Alarm company who had a central station in the building, Chubb Wardens and the Lock and Safe company, who were prime tenants. It was not a happy arrangement as the alarm group had gradually taken over much of the building, leaving the Lock & Safe company with a large and hugely expensive showroom on the ground floor, originally intended to display group products. In addition, we had one floor of office accommodation.

The only space for me was a small derelict office on one side of the showroom, which had originally been the combined telephone and reception office for the whole building. There was no room for a secretary and initially I elected to do without one, using the pool typing facilities on the first floor. The branch staff comprised the manager Ron Jones, an ex Liverpool salesman who had taken the position when I had been withdrawn, an office manager, the Chubb and Chatwood Milner salesmen, the CM manager, together with four Chubb and Chatwood engineers, two carpenters and a number of office staff. All these packed into the space formerly occupied by Chubb Birmingham. Sardines had it easy compared with our circumstances!

Bristol Branch, my other office, was equally cramped, occupying a small shop premises in the central Bristol, in which had been crowded the Chubb and Chatwood sales staff including the former Chatwood Bristol manager; a man by the name of Whiting. It quickly became obvious we had major problems in amalgamating the two sales forces and the focus of these problems, in both branches, was centred round the former Chatwood managers, New and Whiting, who had been demoted to sales representatives on amalgamation. That there was a Chatwood manager in Birmingham was the result of Dick Chapman disobeying instructions by appointing New when the former Chatwood Birmingham manager was moved to Manchester. Chatwood, Birmingham, had 'lost' their sales records in the move but their Bristol records were received intact. From these, John Martin and I were able to see their home sales organisation had consistently broken the rules regarding pricing etc. as I had discovered Chatwood export had done.

In the transfer the Region gained two superb Chatwood salesman, John Jackson in Birmingham, and Mike Coupe in Bristol. Both settled into the new regime well and both had the same curious stories to tell about life under their former managers. Chubb operated exclusive sales areas and all sales in those areas, however obtained, were credited to the area representative. All sales staff could call on the services of their manager or even the regional manager, the position I now held, in dealing with difficult customers or complex orders. This delighted both Jackson and Coupe who told us that previously, their managers would go through the inquiries and the more promising ones would be taken out for the managers attention and credit, in the event of an order. The salesman being left with the dross and less promising jobs.

Having met my staff, the first problem to resolve was that of New and Whiting, the former CM branch managers. I dealt with the situation on a holding basis but did not feel New would settle into being a representative under the Chubb regime. The problem with Whiting was more serious as he quickly became very disgruntled man, and seemed to me, mentally unstable. That his major problem was of his own making, was incidental.

In the amalgamation, the sales projections of both companies for 1971/72 were merged and sales budgets were set on the merged figures. Whiting frequently complained that it was impossible for him to achieve his individual target and make his projected commission, a major part of the salary. From the Chatwood records, John Martin and I discovered that Whiting had grossly exaggerated the sales projections so it was a case of 'being hoist with his own petard', though of course, we all suffered. During the first few months, the Whiting problem became a festering sore at Bristol and John and I spent far too much management time, which we could ill afford with the other pressing amalgamation problems, dealing with the man. Finally, I’d had enough and although we had been given the power to hire and fire staff, it was required we advise our manager of such decisions. At a meeting with Tom Hansell, he assured me that before amalgamation the Chubb and Chatwood directors had carefully weeded out all doubtful staff and it was felt those who remained were totally suitable. Under the circumstances, he ducked the decision and instructed me to see Don Fairclough, the former Chatwood sales director. A meeting was arranged in London and I carefully explained my problem and proposed solution. I fully expected Don would spring to Whiting's defence and give me a dressing down for picking on Chatwood staff. To my amazement, he merely laughed and told me he had experienced all the same problems and had the same misgivings that I had outlined. He went on to say that he should have dismissed him at the pre-amalgamation weed out but had not had the heart to do so because he had been to dinner at Whiting's home, liked his wife and felt sorry for her!

I left feeling very angry at such sloppy management practices by a director and wondering what on earth he was paid for, if not to take difficult or distasteful decisions.

The actual deed was very difficult and I tried to be as courteous and gentle as possible. To this end, I took both Mr and Mrs Whiting to dinner and suggested that it would be to his benefit if he found a new position for himself. Obviously he was hurt and angry with me and told me so in no uncertain terms. To my surprise however, when he left the table for a few minutes, his wife expressed sympathy for my task saying she was not surprised as she’d expected her husband to be dismissed, for a considerable period. Whiting soon found a new job and resigned but I understand he never forgave me and years later was giving vent to his feelings about me, to whoever would listen.

It took me somewhat longer to resolve matters concerning Peter New. He’d been credited as being a high-class salesman but for me, he consistently failed to perform. Whenever challenged about this he always gave the ‘jam tomorrow’ story - that he was negotiating some wonderful contract but didn’t need any assistance in closing the deal. Eventually, after two or three years of poor sales, Peter Keeble (who had replaced Ron Jones) and I, decided to check across New's territory and determine where the best sales opportunities might be. During this check we came upon a large organisation in the depths of the countryside, which had not appeared in any record of sales calls. On returning to the office, we discovered the company in question was in fact part of another representatives area. We asked the salesman concerned, Dick Clark, another ex-Chatwood man, if he had called on the prospect. He replied in the negative but stated that he would do so in the future. The discussion had scarcely concluded when New came into the office in high excitement, stating that he had obtained an order from a new client. Much to our amazement we saw that it was from the company which we had looked at. New was crestfallen when we told him the order belonged to Clark. This incident made us check over New's orders and showed quite a number had been purloined from his fellow sales colleagues, which was regarded in a very poor light by everyone concerned.

After a further year of under performance and again with protestations of jam tomorrow, I gave him a final warning that his orders just had to be in line with target. After another three months with no improvement, I suggested that it would be best if he found another job - the constructive dismissal laws were not then in place - and he left us a few weeks later. Some months on, I met him on a train to London; we had a very animated discussion during which New assured me that leaving was the best thing that had happened to him as he was now earning so much more. I said I was delighted for him but wondered secretly, how much of his earnings were jam tomorrow?

My other ‘CM’ problem was Philip Pascoe, who joined as the Banks Manager - again with a very high reputation. He was a very bristly character and offended many of his banking clients. Finally, a Regional Manager with National Westminster Bank made a complaint about him, to our Northern Region Bank Manager. I was not very pleased when the first I heard about the matter, was an instruction from Hansel to dismiss Pascoe. I felt our northern manager should have had the courtesy to speak with me before going straight to Hansel and presenting me with a fait accompli. To me, it was totally unfair to dismiss the man without any pre-warning about his conduct and I told Hansel so. In the end he gave me permission to retain him as long as he was moved from the Banking Dept. This I did, replacing him with another of my Birmingham representatives, John Merritt. I also met with the National Westminster manager to explain what I was doing.

Phil however, proved to be a continuing problem for me, particularly after the breakdown of his marriage. In my opinion, he was as much to blame. He’d become obsessive about women and would bore people to death with accounts of his wife's infidelities and his own conquests. He had a very chequered career after leaving Birmingham, having a spell with export before moving to manage our Greenwich branch and being made redundant when it was closed.

Generally, life in the early days following amalgamation was interesting and eventful with a great deal for the Regional Manager to do. One of my main concerns was the lack of training of the home salesmen, many of whom seemed to know little about the company products. I was determined to alter this unhappy state of affairs for my own sales force and spent a great deal of time in the field with them. I also increased the size of my service department and gave them a great deal more mobility. Previously, Chubb had purchased service vans and there were never enough vans for all the engineers. I was advised that if I leased vans, they would not show on my capital budget and could be paid for out of income. This was the route I selected and in due course all the Birmingham engineers had their own van which gave them tremendous mobility. This saved a great deal of the time that was previously wasted when they had to rely on public transport. Most of my engineers were ex-Wolverhampton apprentices and to ensure the greatest flexibility I paid them all at the top rate on the proviso they do any job given to them, even if it was assisting in a door installation, as a labourer. At other branches, particularly in London, engineers were given specialist jobs, together with bricklayers and labourers. As a result, there were many occasions when these ‘specialists’ were unemployed. In our case, we had very little downtime and consequently, the returns from our service department were much higher than expected by senior management. Part of my remuneration was based on the profitability of the region so this extra service department revenue, increased my bonuses handsomely.

Initially, the Regional General Managers were John Dewar (South East), Stuart Smith (Northern), Ian Radcliffe (Scotland) and Ted Hewitt (Ireland). Originally, Johnny Johnston had been offered the job in Scotland but rejected it, possibly because he thought it would be too hard. After a relatively short period, Stuart Smith, who I always found to be a rather abrasive character, accepted the position of Sales Director in Chubb Australia. Sadly, he did not last very long in the job and resigned from the company, but more of this later. As a result of this move, Ted Hewitt was transferred from Ireland to Manchester and Mike Dempsey was given the Ireland post. Quite how this came about I have no idea; at our monthly conferences he was quite ineffective and subsequently left Ireland under somewhat dubious circumstances, and returned to export.

The then managing director, Alfred Markham, decided to chair a monthly meeting of the regional managers and Reg Milne, the Works Accountant, to discuss how to overcome mutual problems following the amalgamation. After some months most of the major problems were resolved but the monthly meetings continued. In due course, Alfred was replaced as managing director, by John McArthur, formerly the Financial Director. The monthly meeting was an ideal opportunity of making suggestions to improve the operations although it was obvious to Ted and myself, our three colleagues did not appear to suffer the sort of problems which plagued us. We therefore decided I would join Ted on the train at Birmingham New Street and we’d agree our policy for the meeting during the journey to London.

One of the problems which took up a great deal of our time, concerned the poor quality of design at the factory. By the time of the amalgamation, Trevor Braybrook, the Works Director, had been replaced by Charles Barton, who in turn, had brought in a lot of his own people. One of these was James O'Neill Fisher, who became the chief designer. He had got off to rather a bad start, when he was introduced at a sales conference and had spoken about the design function. Unfortunately, he had rashly suggested he felt plastics had a considerable part to play in the safe making industry. Thereafter, he was known as the Plastic Fisher. It appeared he had previously been employed in the white goods industry and felt he could introduce the mass production techniques in that industry to the benefit of Chubb. To this end, all his designs required drawings and planning for even the most minor item and in the event of a modification, all drawings and planning needed to be recreated. In truth, Chubb was little more than a jobbing blacksmith as in many cases, clients required that our standard products be slightly modified to meet their requirements. In the past, this had been done by issuing a standard drawing together with the modification requirement. This was quick and cheap to implement as our highly skilled craftsmen were able to carry out the modifications to these basic drawings.

Fisher’s system soon had us bogged down in paperwork and any specials took so long to produce and were so costly, that I know we quickly lost our reputation as a 'can do' company.

Plastic parts were introduced as forecast, with disaster following disaster. I first became aware of serious problems when one of my engineers reported that a 3½ inch vault door which he had installed, needed all his strength to open and close. He felt the female staff at the bank would not be able to operate the door. In the past, such doors could be moved with one finger once the initial inertia was overcome. I was both worried and curious so instructed the engineer, himself a Wolverhampton trained apprentice, to ask his colleagues in the Factory, whether they could throw any light on the problem. He came back some days later with a troubling story. New vault doors were being fitted with a plastic impregnated paper plain bearing in lieu of the traditional phosphor bronze bushes. I immediately paid a visit to Wolverhampton and spoke with Arthur Tyson, the charge hand on the door section, who had been one of my training supervisors during my own apprenticeship. He confirmed the plastic bearing story and advised me the serial number of the door first fitted. He told me he had reported the heavy movement problem but no action had been taken. He also referred me to the head of the prototype section where the new bearing had first been tested. I was shown his report to Fisher, recommending no further use be made of the plastic bearing, which was intended for shafts rotating in liquids, a use totally dissimilar to the door hinge application. He also showed me the modification sheet, signed by Fisher, authorising the use of the new plastic bush in the doors.

Extremely worried, I wrote to my boss Reg Pilgrim, expressing my fear that many doors in the field would need the plastic bearing replaced - two days work in all, which would bear heavily on the rectification account. Reg, quite correctly wrote to the works on behalf of sales, to inquire what was going on. Shortly afterwards I received a petulant note from Fisher, expressing his dismay that I had not had the courtesy to advise him of the problem, rather than my immediate director. He went on to say he had no idea of the introduction of the bearing, which he certainly would not have sanctioned. I replied rather sharply, advising that I had followed correct protocol in writing to my immediate boss and expressing my amazement that he had no knowledge of signing the authorising modification sheet! As I’d suspected, quite a significant number of doors had to be modified, many of these being in the Midlands area, which cost my engineers a great deal of time.

The next plastic disaster proved to be not only expensive but a major embarrassment for us in the eyes of some of our most important clients. For years the system of disconnecting the external bolt throwing handle from the the internal mechanism of the safe door, had been seen as an excellent form of defence against forcible entry and particularly an explosive attack. The first attempt at such a system was a poor design and quickly needed to be modified. The modification came in the form of the isolater locking mechanism, brilliantly conceived and designed by Ron Swift - an ex apprentice and a first-rate design draughtsman who had been nurtured by David Tate, the previous chief designer. Essentially, the system comprised a clutch, not dissimilar to that on a motorcar. The clutch was controlled by the master lock, engaging when the lock was opened and disengaging when the lock shot. The fork which actually operated the clutch was initially produced in a dense polystyrene material. The locking mechanism fitters were instructed to apply a lubricant grease during assembly so that the unit would be virtually maintenance free for its lifetime. Unfortunately, Fisher did not appreciate that polystyrene and grease do not mix and within 12 months, the clutch forks collapsed, which caused many lockouts on the doors and safes fitted with these units. A replacement clutch fork was issued, this produced in glass reinforced nylon. Unfortunately, Fisher did not appreciate that this material was subject to age shrinkage and again, in approximately 12 months, this shrinkage caused a lockout. We faced the very embarrassing situation of attending to safes yet again to rectify a manufacturing fault. As this type of mechanism was fitted to our highest quality safes, which were purchased in quantity by the banks and other important clients, I believe this repeat fault caused our reputation for quality to be much downgraded. The third replacement clutch fork was made in scintered iron and although this avoided all the previous problems, it was not made in-house. In due course this third replacement was in turn replaced by a fabricated pressed steel unit, which in my opinion should have been used in the first place.

From a Regional Manager’s point of view, these lockouts and replacements cost us a great deal of engineering time. Although the engineer’s hours were charged back to the factory rectification account at cost, those hours, which could have been ‘sold’ at a profit, were not available and thus had a bearing on the Regional Manager’s bonus.

The final disaster which as far as I was concerned, was the last straw, related to a new Data Protection Cabinet. Our previous DP Cabinets had been based on paper protection Cabinets, suitably modified. The new Cabinet was purpose designed to suit the smaller computing user. Previously, only the largest companies had data processing departments but with the rapid development of smaller computers, even medium and small companies were carrying out their own data processing and needed protection for the computer records. The new Cabinet met the market needs and we were very successful with it. Again, this was a Fisher design and in the interests of economy, he decided the door bolt mechanism should be held in place by star lock washers. There was nothing wrong in this as the motor industry had used them for many years to fix the door winding gear on motorcars. All that was required was that the stud and the star lock washer should be correctly matched. Unfortunately, the door studs were under size for the washers used and after a few months operation, the washers became detached from the studs, allowing the boltwork to collapse and the unit to lockout. As the engineers couldn’t determine which of the washers had become detached, it was very difficult to open the unit. After consultation with the factory it was decided that any locked out data Cabinet must be returned to the factory for rectification. This arrangement caused a great deal of concern to one of my clients, who was using the Cabinet to store the large multi-plate Winchester disk. This disk was very prone to damage if it were dropped and the data manager was most concerned that this might occur during its transit to the factory. He advised me in no uncertain terms that if such damage occurred, his company would look to Chubb for recompense in recreating the data held on the disk.

I contacted Ted Hewitt and asked how his engineers had fared with all the rectification work. Like me he was furious, not only because of the damage to the Company's reputation but also the reduction in his quarterly bonus based on profit from the engineering department. Between as we resolved to raise this matter at the next regional managers general meeting. As always the meeting was chaired by the M.D., John McArthur, an accountant by profession. By agreement with Ted, we'd both laid the problems on the line to John, stressing both the reputation and the profit angle. The other three regional managers, whom we had previously consulted had little to say on the subject but in due course, John Dewar, regional manager for the South, seeing how the meeting was going, joined in, saying that in his opinion, Fisher was totally incompetent. At this, John McArthur, who could see how strongly we felt about the problem, asked what he should do. Unanimously, we decided that Fisher should resign and by the end of the meeting, McArthur fully agreed with this solution. We were vastly disappointed when it did not occur and at the next monthly meeting, asked John McArthur for an explanation. He advised us he had returned to Wolverhampton that night, called for Barton, the Works Director, and told him he required Fisher's resignation because of the problems which had occurred. Apparently, Barton stated that if Fisher resigned he would have to resign as well. John admitted that this rather called his bluff and it was agreed that Fisher should be reprimanded. All the Regional Managers were furious and stated that he should have accepted both resignations since Barton had brought in Fisher and should therefore be responsible for the standard of work created by him.

These problems apart, the service department at Birmingham went from strength to strength. In due course, we took over all installation work from the private contractor J. B. Baker, who was running his business down as he got older, being unable to cope with the volume of work we were offering. We had a special delivery lorry produced by our car rental company, which incorporated a Hiab crane - a novel feature for Chubb delivery wagons which had previously used tail lifts.

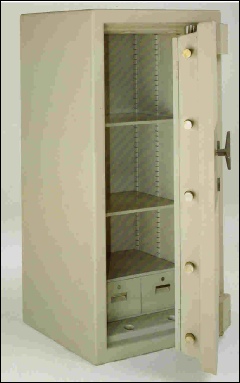

Another innovation I introduced to Birmingham was to re-purchase used Chubb, Chatwood and Hobbs safes. Previously, Chubb had not dealt in second-hand equipment so these items had been purchased by dealers, of which there were many in the Birmingham area. This trade in second-hand equipment had caused our salesmen and great many problems, particularly in the Birmingham jewellery district, many orders for new safes being lost due to our rather slow factory delivery. Our first opportunity came from one of our Coal Board clients, who was required to hold very large sums of cash for wages. This client was instructed by the insurers to replace a large number of Chubb third strength Bankers safes, with the recently introduced Chubb . Bankers Treasury safes. The chief accountant of the coal board insisted we accept the existing units in part exchange. I readily agreed, allowing him the sum of 220 pounds per safe. On return to our showroom, I had the engineers check over the units and introduce all the latest modifications. The safes were also repainted and when finished, looked to be in pristine condition. Each safe was originally fitted with the Chubb 7L60 mechanical time lock, which we replaced with an up to date model.

Another innovation I introduced to Birmingham was to re-purchase used Chubb, Chatwood and Hobbs safes. Previously, Chubb had not dealt in second-hand equipment so these items had been purchased by dealers, of which there were many in the Birmingham area. This trade in second-hand equipment had caused our salesmen and great many problems, particularly in the Birmingham jewellery district, many orders for new safes being lost due to our rather slow factory delivery. Our first opportunity came from one of our Coal Board clients, who was required to hold very large sums of cash for wages. This client was instructed by the insurers to replace a large number of Chubb third strength Bankers safes, with the recently introduced Chubb . Bankers Treasury safes. The chief accountant of the coal board insisted we accept the existing units in part exchange. I readily agreed, allowing him the sum of 220 pounds per safe. On return to our showroom, I had the engineers check over the units and introduce all the latest modifications. The safes were also repainted and when finished, looked to be in pristine condition. Each safe was originally fitted with the Chubb 7L60 mechanical time lock, which we replaced with an up to date model.

Remembering the 7L60 was very popular in West Africa, I contacted Nigel Cartwright in export, and inquired whether the locks were of interest to him. He was delighted to learn that the locks were available and agreed to pay 250 pounds each for these, after they had been reconditioned by the watchmaker. All the safes were sold by Chris Stanley in the jewellery quarter within six weeks, at approximately three quarters of the price we would have received for the latest Bankers Treasury safes. Even allowing for the transport, reconditioning, painting and the cost of buying in, the return we made on these units was so high that the accounts department in Wolverhampton, made a very thorough check before crediting Birmingham with the profit.

Everyone was pleased; the Coal Board who felt they had a good deal, Chris Stanley who was able to obtain orders which would have previously gone to the second-hand dealers and Peter Keeble and I who benefited in our bonuses. After this I instructed that any group name safes would be re-purchased, the better quality ones to be reconditioned and used in those cases where competition from dealers precluded the possibility of a new order. The older units were to be cut up and sold for scrap. In this way, we greatly reduced the number of better quality safes reaching the second-hand dealers and ensured that the older, lower quality units, were destroyed instead of being sold by some of the unscrupulous dealers to unsuspecting customers. Sometime later, Tom Hansell, who returned from Holland to again be sales director, decided that the company would no longer deal in previously used safes and in my opinion did the company a great disservice.

Bankers Treasury Safe

Home | Previous Page | ToP | Next Page

| Chubb 1818-1990s |

| Chatwood-Milner |

| Chubb Family |

| Early Sales/Offices/ChubbGroup/1980s & on |

| The Detector Mechanism |

| Photographs |

| Chubb Money Boxes |

| The Aubin Trophy |

| Lock Number 696 |

| Williams acqusition |

| Arthur Briant |

| Ibbs - Export is Fun |

| Peter Gunn |

| Back to Work |

| First Steps |

| My Export Career begins |

| The Happy Years |

| Export Manager |

| Back to The Midlands |

| Back to The Midlands - part 2 |

| Australia |

| The Midlands - again! |

| The Final Years |

| Conclusions |

| Slingsby Dart T51 Sailplane |

| Latest News |